29.10.2025

Supply Chain Optimisation: A Performance Accelerator

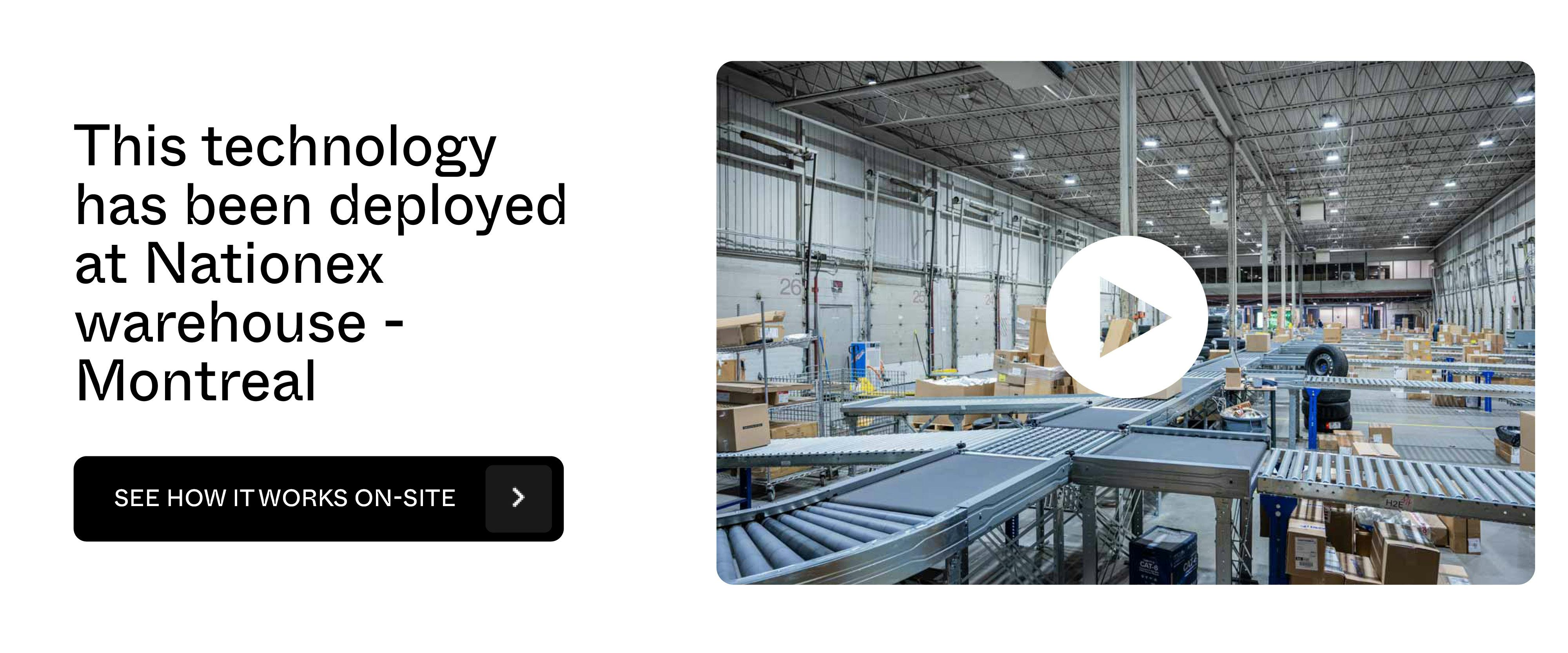

This sentence, spoken after the commissioning of a complete conveyor solution at Nationex, perfectly sums up a now-common logistics challenge: moving fast, very fast... but doing it well.

With more than 220,000 parcels delivered each week and the pressure of Black Friday looming, the Canadian carrier had to rethink its sorting system, with no room for error. How do you optimise a supply chain under pressure while speeding up implementation times?

That’s where Boa Concept's modular technology comes in.

Why Supply Chain Optimisation Is No Longer Optional

Rising volumes, mixed formats, unpredictable activity peaks: today, companies need systems that can increase speed, handle throughput, and remain flexible as requirements evolve.

For many, this comes down to the following challenges:

✔️Reduce the installation times of automated solutions,

✔️Simplify architectures to speed up commissioning,

✔️Equip themselves with lines able to handle different formats,

✔️Anticipate peaks like Black Friday.

Nationex perfectly illustrates these challenges — and how to overcome them.

The Boa Concept Approach: Plug-and-Play in the Strictest Sense

One of the key performance factors in logistics is the time required between decision and operational go-live. Boa Concept has developed a simple philosophy: industrialise upstream, to deploy faster in the field.

How?

1. Standardised, prewired, pre-tested modules

Each conveyor element is assembled and checked in the workshop. On site, installation becomes an assembly operation — like a plug-and-play system.

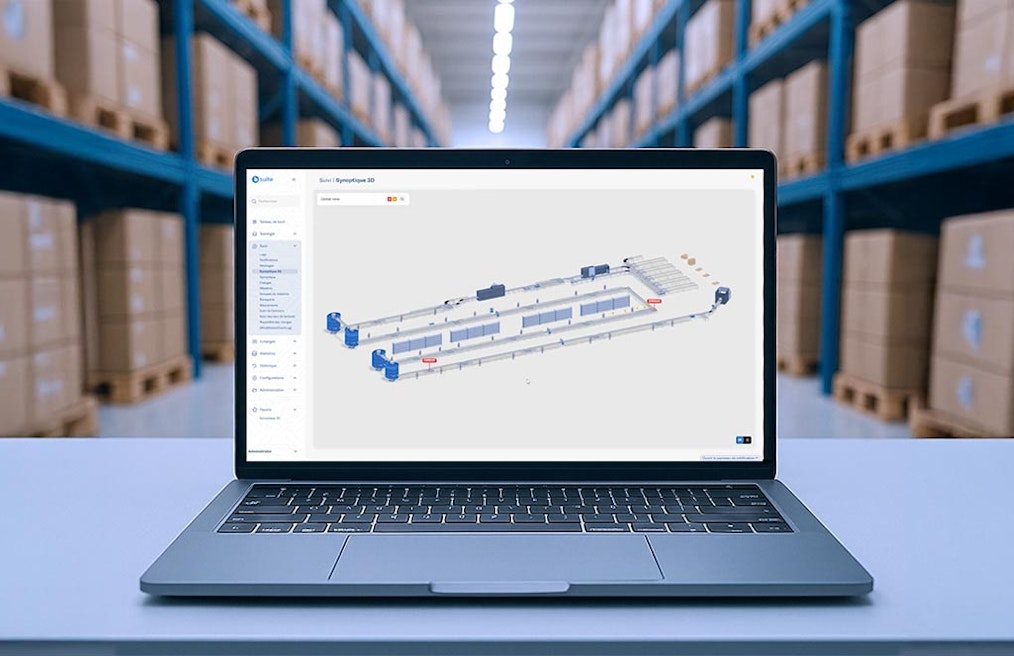

2. Decentralised intelligence, no programmable logic controller

Each module is autonomous and automatically recognised by the supervisory software. The result:

✔️No complex programming,

✔️Accelerated commissioning,

✔️Easy for IT and operations teams to get to grips with.

3. An architecture that makes life easier for teams

Both technicians and operators gain autonomy: operation is clear, adjustments are limited, and changes are quick to make.

When Good Design Transforms Field Operations

For Nationex, this technological choice not only ensured ultra-fast deployment, but also secured the ramp-up of the Montreal hub. The project was carried out jointly by: IT teams at Nationex, Boa Concept experts, Electrotech Industrial Automation, Granby (electrical integration), whose work was praised as "excellent".

The Boa technology arrived ready to go: with all power and control connections pre-fabricated, in certified quick-connect and meeting CSA/UL requirements, drastically reducing the usual time spent on wiring.

This project demonstrates an important principle: supply chain optimisation is not just about equipment — it’s about overall architecture.

The Benefits of an Agile Supply Chain

Modular, intelligent technology enables you to achieve three goals:

✔️ Save time

Shorter deployments, faster commissioning, less dependence on bespoke programming.

✔️ Gain flexibility

Lines can be moved, modified, extended — a major asset in highly seasonal environments.

✔️ Improve performance

A system capable of handling varied formats, without interruption, improves fluidity and sorting capacity.

Conclusion: An Inspiring Example of Supply Chain Optimisation

The Nationex x Boa Concept project demonstrates that modular innovation + embedded intelligence = an optimised supply chain, ready to absorb activity peaks and support growth.

Proof that in an ever-changing sector, performance isn't just about moving faster... but about moving faster while staying flexible and reliable.

About Nationex

Nationex, the leading Canadian parcel carrier certified B Corp, has established itself as a leader in sustainable transport. The company places innovation and environmental responsibility at the heart of its model to provide reliable, efficient, and environmentally friendly delivery solutions. Its mission is to offer high-performing transport services while ensuring an exceptional customer experience. With a forward-looking vision, Nationex is actively shaping more sustainable logistics and building a greener future for generations to come.