11.12.2025

Automate Your Warehouse: From 500 Parcels a Day, It’s Possible!

It’s often thought that logistics automation is the preserve of e-commerce giants. Yet, from 500 parcels a day, you can already automate your picking and shipping operations. The result? Time, reliability, and energy savings… and better service quality.

See below for the example of a responsible fashion e-merchant company that combines logistical performance with ethical commitment.

1. Giving Unsold Stock a Second Life, Without Compromising Efficiency

What should be done with stock remaining after sale seasons?

The company positions itself as a simple, instant, and responsible solution for retailers wanting to add value to end-of-line stock.

Based in France, works with over 2,500 stores and e-commerce sellers all across the country to help combat textile waste.

Their promise?

· Add value to unsold stock from physical retail

· Help retailers manage their inventory sustainably

· Make responsible fashion more accessible

The model is built on 3 pillars:

· Every item deserves its chance.

· Every shop deserves a reliable and sustainable solution.

· Every consumer deserves quality, durable, and affordable fashion.

3. The Challenges of a Growing E-merchant Company

Like many e-commerce brands, they faced several logistics pain points:

· Effectively managing activity peaks

· Reducing the number of boxes used

· Standardising loads into envelope format

· Meeting carrier constraints

· Automating the sorting of orders by carrier

· Streamlining the picking and dispatch area

· Optimising low value-added roles

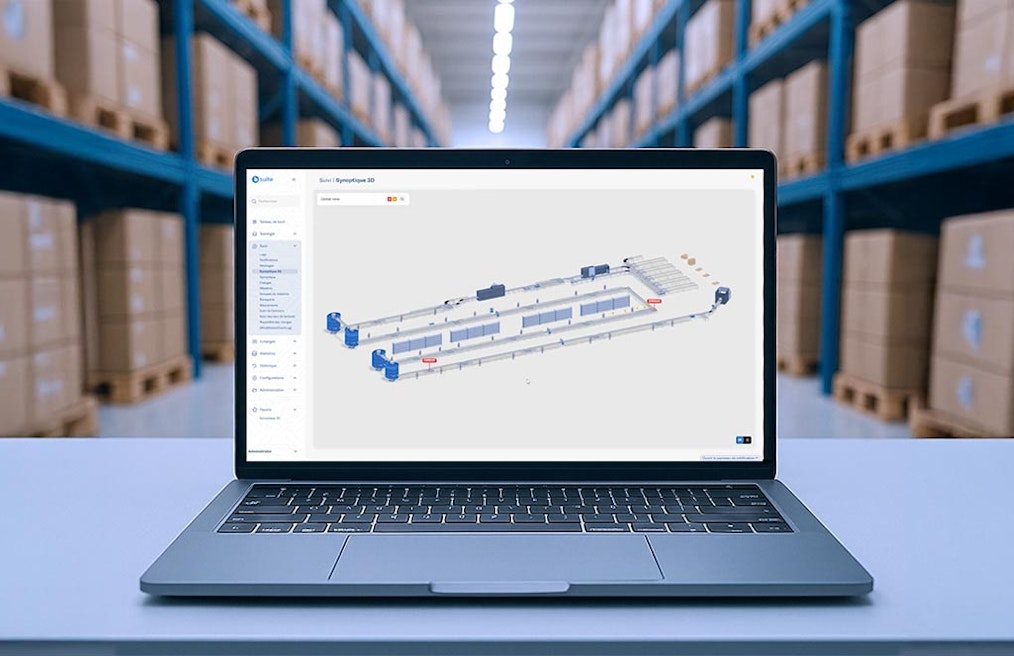

4. Automation by Boa Concept: Modular, Scalable, Sustainable

To address these issues, Boa Concept deployed a tailor-made automation solution:

· A complete automated line, designed for small parcels

- Load transfer with motorised belt conveyors

- Presence detection to activate/deactivate only when required → saves energy

- 100% electric operation, quiet and ergonomic

· Automated carrier sorting

Thanks to a connected reading gantry, each parcel is scanned in real time and automatically routed to the roll cage for the correct carrier.

· No more manual sorting

· Fewer errors

· Saves time and energy for the operators, who can focus on higher-value tasks

5. And Tomorrow? Scalability Already Built In

Growth never hits pause. Why should your logistics? Boa concept keeps pace with scalable solutions

· Sized to support growth and designed to absorb rapid increases in activity.

· Modular, can be adapted to order volumes.

· Our teams can review the setup at any time to deliver new productivity gains.

We are proud to support logistics transformation

· Because performance and sustainability are not mutually exclusive

· Because every player can choose a virtuous model

· Because an automated warehouse, even handling 500 orders a day, is no longer a pipe dream