11.12.2025

More Agile Logistics for Rexel

When it comes to logistics optimisation, an efficient solution alone just isn’t enough!

Optimising logistics for distributor retailers isn’t just about having an efficient solution — it’s also about agile and effective collaboration. That’s exactly what the Boa and Rexel teams achieved together for the project to relocate and modernise a logistics warehouse in Saint-Martin-de-Crau, France. This winning partnership proves that with a modular and agile approach, the supply chain can genuinely be transformed for the long term.

A major logistics challenge

With a logistics warehouse increasing from 18,000 sqm to 32,000 sqm, Rexel faced a real logistics optimisation challenge: ramp up activity by 1.5 times while ensuring smooth processing of 16,000 order lines per day.

Its old conveyor system, although robust, could no longer meet the group’s requirements for flexibility and scalability. Integrating a more modular and scalable solution was therefore crucial. Boa Concept emerged as the ideal partner to respond to these challenges.

Sébastien Fafin, Supply Chain Project Manager at Rexel, sums up the challenge

Logistics optimisation through agility and collaboration

Following a rigorous call for tenders, Rexel chose Boa Concept for its agile approach and ability to co-develop optimised solutions.

Sébastien Fafin explains:

Unlike other players in the market, Boa Concept showed remarkable flexibility, a key advantage in a project requiring constant adaptation.

Innovative solutions for optimised logistics

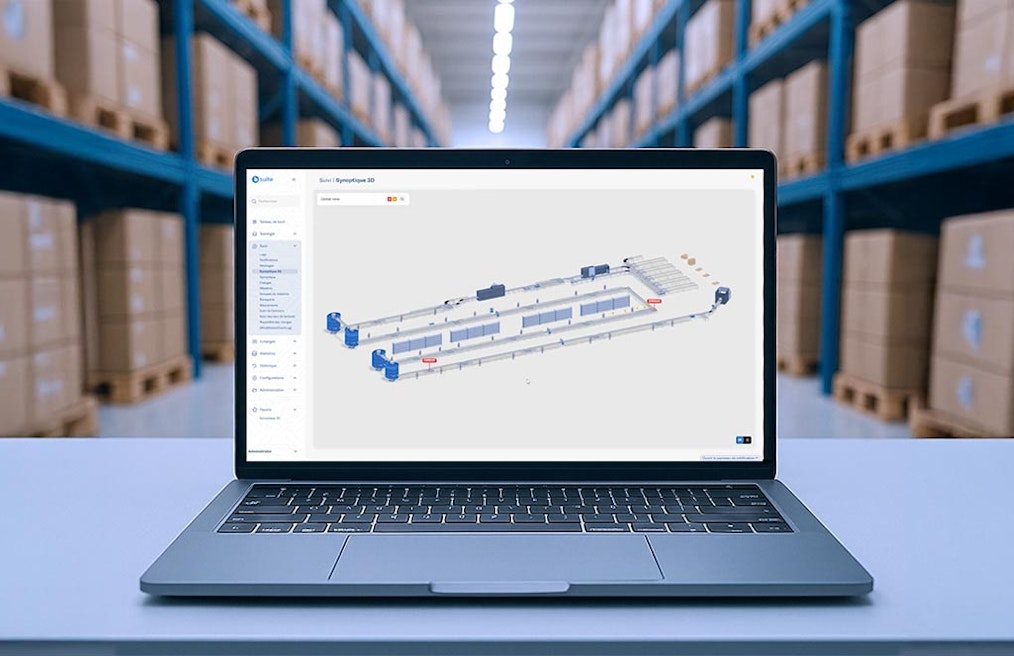

The logistics optimisation implemented relies on several innovations:

✔️ A modular conveyor system that can be easily reconfigured as needed.

✔️ Packaging and sorting solutions that optimise shipments.

✔️ Seamless interfacing with Rexel’s information system ensuring efficient flow management.

Thanks to Boa Concept’s agility, productivity was able to be optimised gradually.

Positive results and ever more efficient logistics

The results speak for themselves:

✔️ Increased processing speed, from 900 to 1,200 parcels per hour.

✔️ 16,000 order lines processed daily with a 99.5% service rate maintained.

✔️ Reduced cabling and simplified maintenance.

✔️ Additional accumulation lines for better management of peak loads.

✔️ Optimised shipments with 3 chutes and 15 sorting destinations.

The installation was quickly refined with targeted maintenance and adjustment measures. Close monitoring and periodic visits have helped sustainably boost logistics performance.

Asked for his feedback, Sébastien Fafin is unequivocal:

Thanks to this collaboration, Rexel has achieved its performance goals and secured a future-proof solution. It’s proof that logistics optimisation is just as dependent on technology as on a solid, agile partnership.

About Rexel

Rexel is a key player in multi-channel distribution of electrical equipment and energy solutions. Operating in the B2B market, the company supports professionals with innovative and sustainable solutions tailored to energy efficiency challenges. Its network of 460 branches ensures optimal coverage and highly responsive local service.

Committed to ultra-efficient logistics, Rexel prepares orders placed before 6pm and delivers them the very next day before 7am to any of its 460 network branches. With a service rate of 99.5%, customer satisfaction is a top priority for the company.