18.06.2025

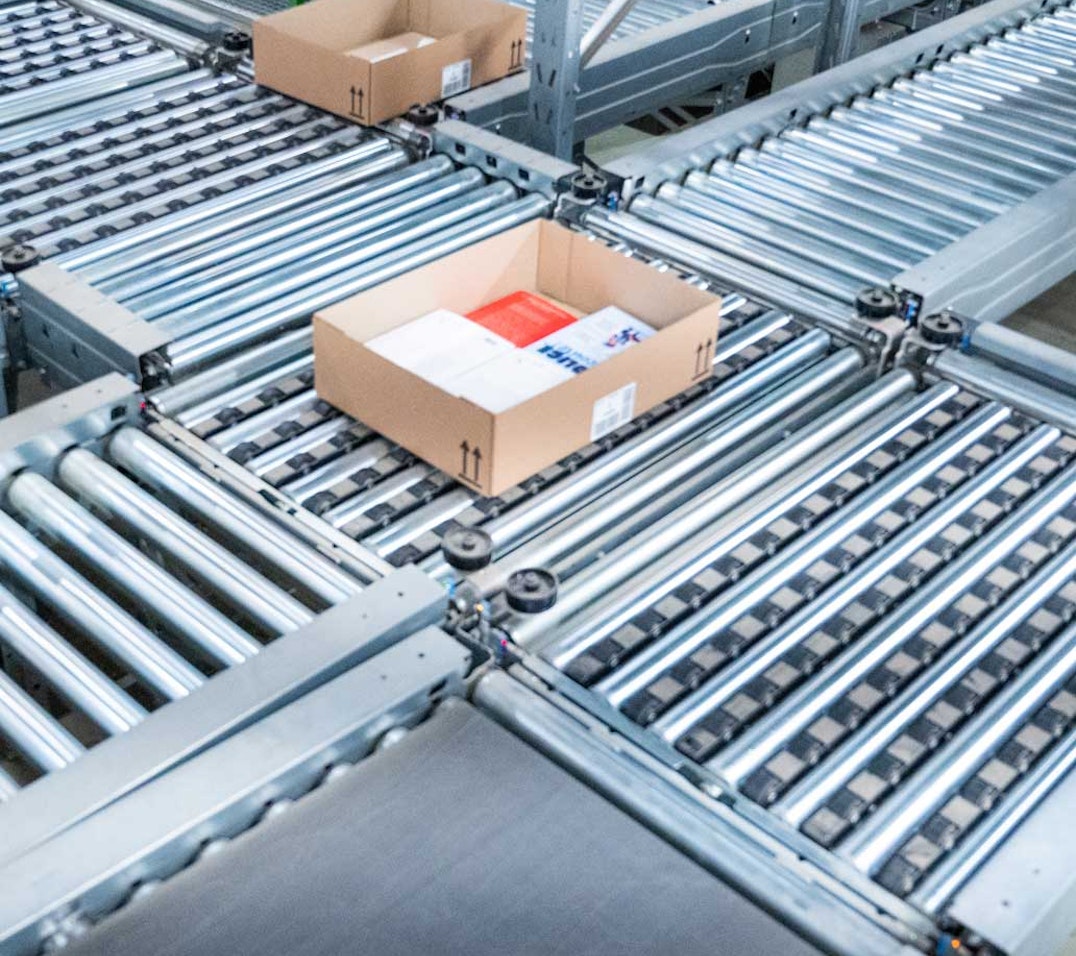

Bringing the future

of logistics to life

Our commitment

The key to your logistics success

01

Modularity

Adapt your logistics to your needs

Modify your setup in real time

Reconfigure without interrupting operations

02

Intelligence

Optimize your logistics flow with IoT

Reduce errors, increase efficiency

Monitor and adjust in real time

03

Reliability

Expert teams available 24/7 via our hotline

95% of problems resolved remotly

Technical assistance and preventive maintenance ensured

Get a quote

Our solutions

Entrust your team's with data analysis,

and let our robots handle carton management

Entrust your team's with data analysis,

and let our robots handle carton management

They trust us

Navigation

With Boa Drive,

manage your supply chain

at your fingertips

With Boa Drive,

manage your supply chain

at your fingertips

Accelerated deployment through automation

Real-time control of your line

Live performance indicators

Take control of your supply chain in real-time, wherever you are. Our intuitive software optimizes your workflow and streamlines your decisions-making—accessible from smartphone to your workstation. Manage your supply chain, with a single click.

Learn more

News

Discover our latest news

Career space

Shape the future of

logistics with us

Passionate about innovation? Join Boa Concept and transform the future of intelligent logistics! Discover our opportunities on Welcome to the Jungle and join a dynamic team where your ideas will come to life.